Industrial robot

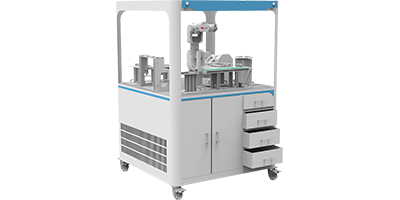

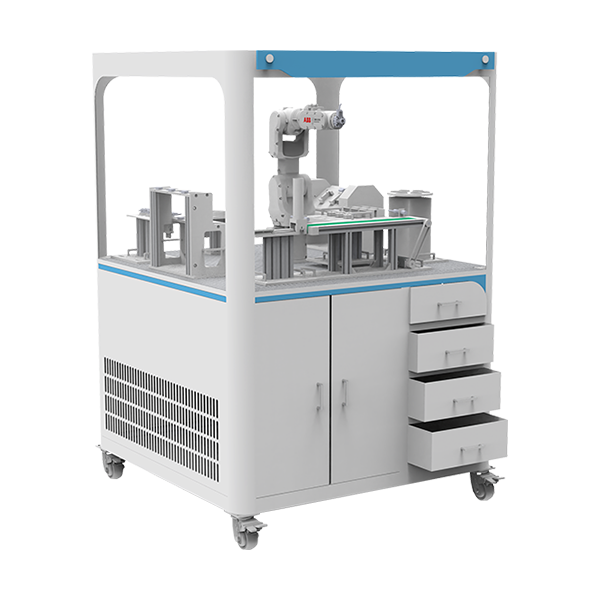

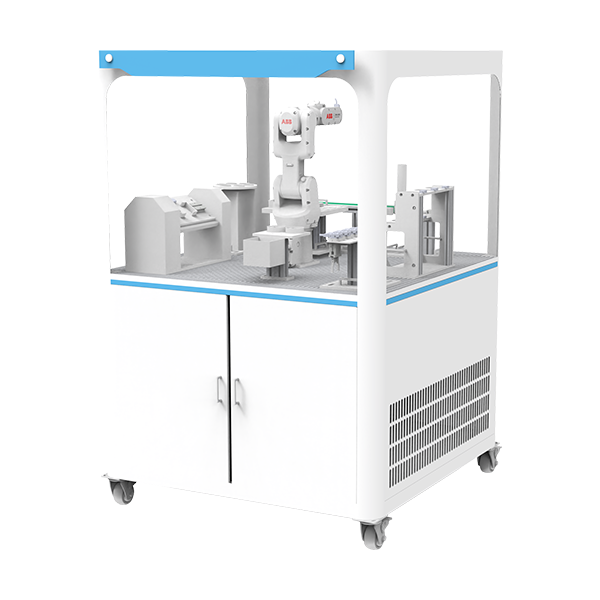

Industrial Robot Training Equipment

Our industrial robot training equipment adopts the latest generation of industrial robot bodies, equipped with advanced controllers and teaching aids, ensuring that you are exposed to the most cutting-edge automation technology. We can provide comprehensive training experiences in material handling, trajectory simulation, and arc welding technology.

Product Features

Easy to program

Provide an intuitive and easy-to-use programming interface that supports graphical programming or simple programming languages, making it easy for beginners to quickly get started.

simulation software

Integrated virtual simulation software allows users to conduct simulation training before actual operation, reducing error costs.

Multipurpose

Can simulate tasks in various industrial environments, such as assembly, handling, welding, spraying, etc., to improve the effectiveness of practical training.

Teaching resources

Usually, detailed teaching materials, experimental guides, and online tutorials are provided as auxiliary materials to facilitate teachers' teaching and students' self-learning.

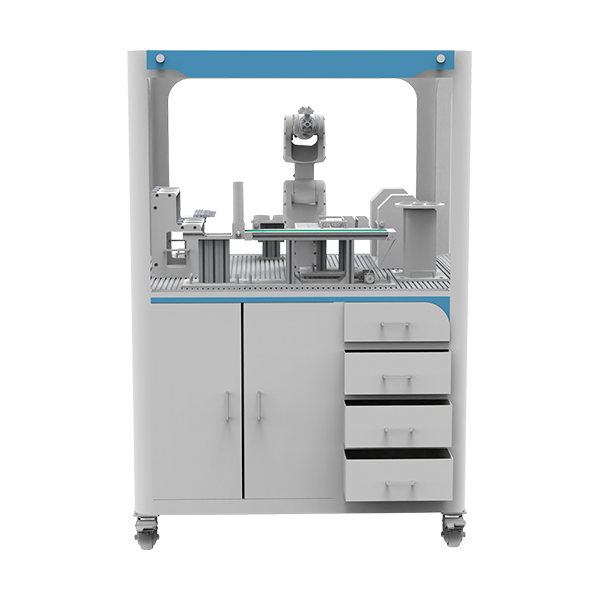

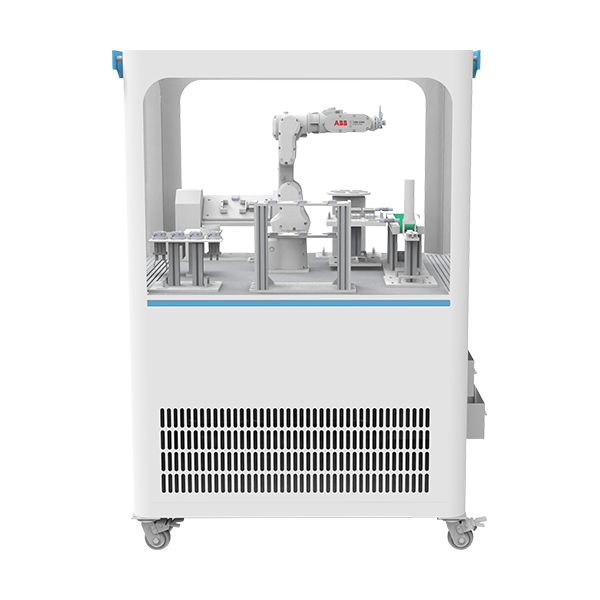

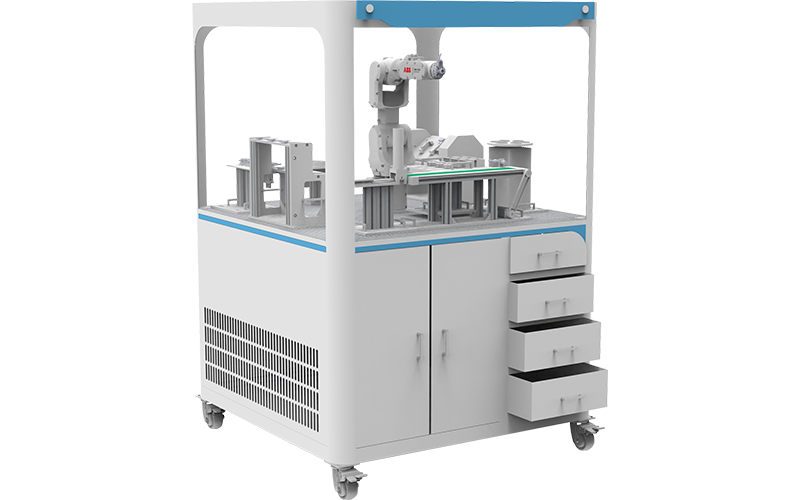

Group Display

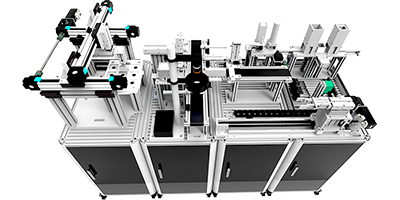

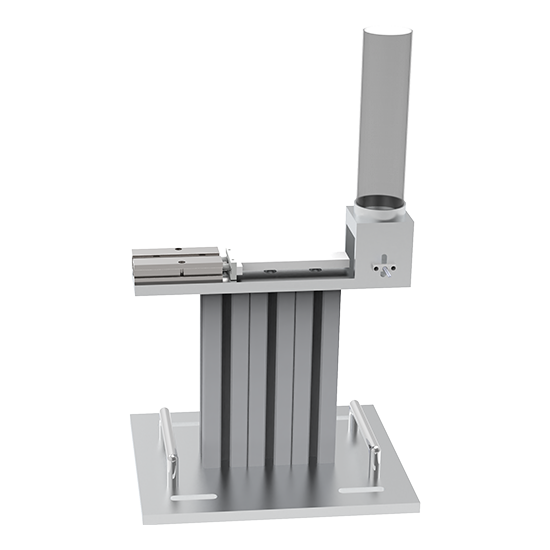

Material supply workstation

It mainly consists of a fixed base plate, stainless steel handle, support frame, installation plate, cylinder, push rod, organic material barrel, etc., and is made of aluminum alloy material as a whole. Used for storing materials to be assembled, this module can be controlled by a PLC controller to achieve automatic outbound operation of the materials to be assembled. This module is used in conjunction with the conveying unit.

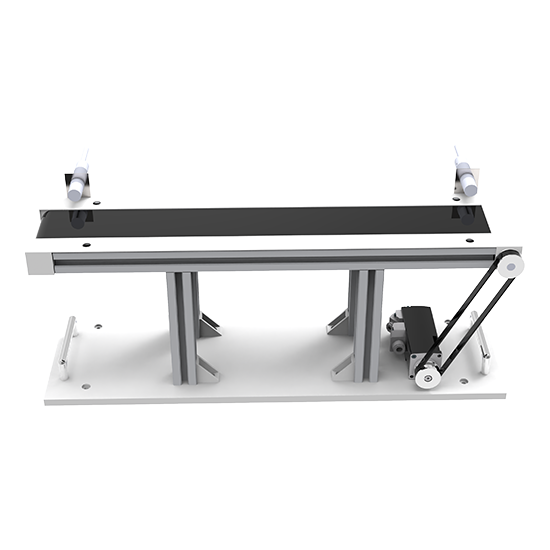

Conveyor unit

It mainly consists of a fixed base plate, stainless steel handle, support frame, belt, bearing, driving wheel, driven wheel, driving motor (with multiple driving modes including DC, AC, stepper, and servo), rotary encoder, photoelectric switch, and guide plate. The overall material is made of aluminum alloy and stainless steel, used for conveying the well type feeding and outbound model. The unit can be controlled by a PLC controller to achieve automatic transportation of materials. This module is used in conjunction with a well feeding unit and a visual inspection unit.

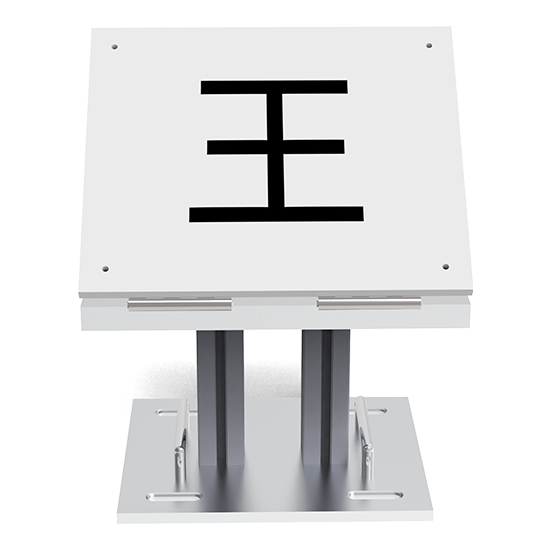

Drawing unit

The drawing module is divided into two types: flat drawing and surface drawing, mainly composed of drawing fixed brackets, drawing boards, stainless steel handles, support rods, etc. Reserved workpiece coordinate system calibration points on the flat drawing board can be used to calibrate the coordinates of industrial robot workpieces. This module supports surface trajectory drawing, and through manual operation, it can achieve the function of drawing inclined plane trajectories at various angles; The curved drawing board adopts an arc-shaped design, which can be used for training spatial posture teaching exercises.

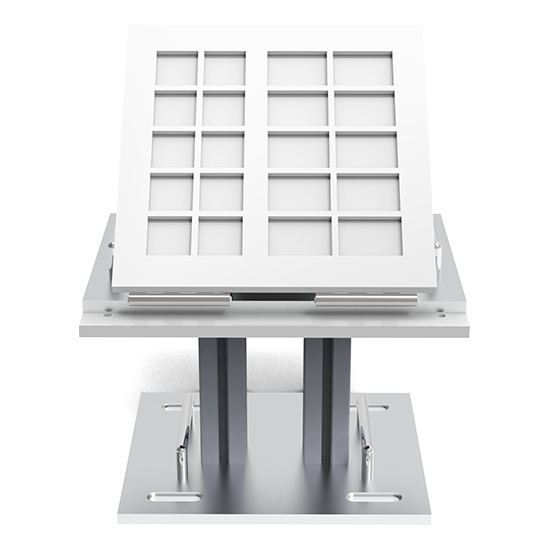

Slope handling unit

The inclined plane handling operation module mainly consists of handling brackets, handling panels, handling workpieces (triangles with numbers), stainless steel handles, etc. The handling panel is divided into two material panels, left and right, with 10 reserved square and rectangular placement positions. At the same time, a workpiece coordinate system calibration point is reserved, which can be used to calibrate the coordinates of industrial robot workpieces.

The conveying unit is used in conjunction.

Product Introduction

No information available at the moment