Industrial robot

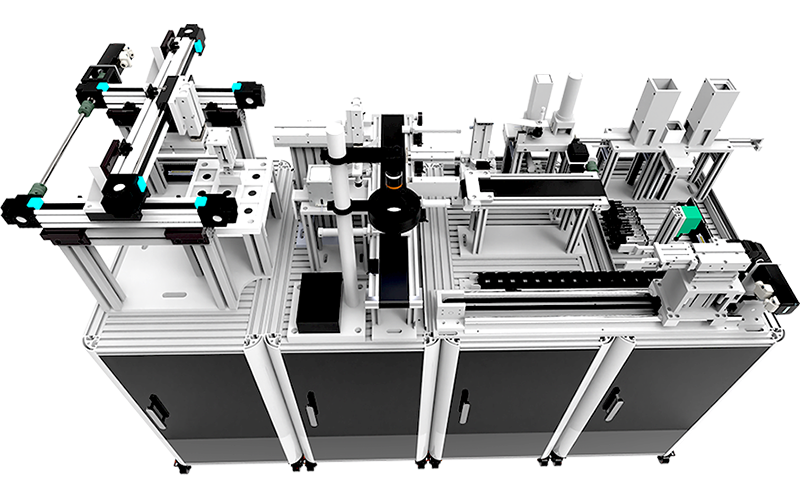

Virtual real combination production line training equipment

Our equipment adopts the latest industrial robotic arms, combined with advanced vision and controllers, to ensure that you are exposed to the most advanced automation technology. Whether it's material handling or trajectory simulation, we can provide a comprehensive practical training experience.

Product Features

Module design

The device adopts a modular design, which is easy to move, easy to update and iterate in the future, and can replace modules separately, reducing maintenance costs.

Comprehensive technology

The equipment covers technologies such as interconnection, transmission, human-machine, vision, machinery, sensing, and communication.

Integration of Industry and Education

The equipment is close to the actual particle filling production line, which facilitates the integration of schools and enterprises in industrial teaching.

selective focus

The equipment is equipped with simulation models and supports digital twin hardware expansion.

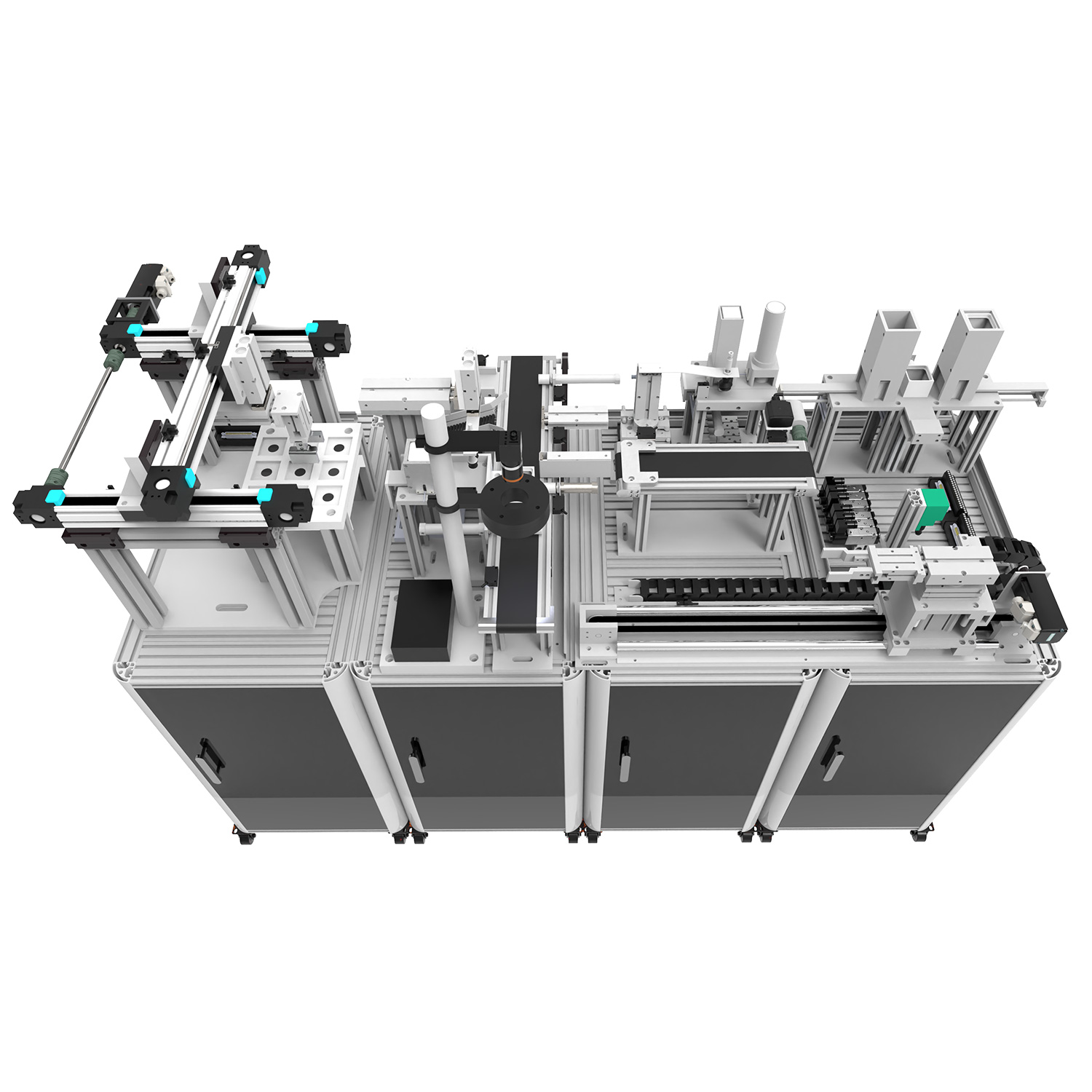

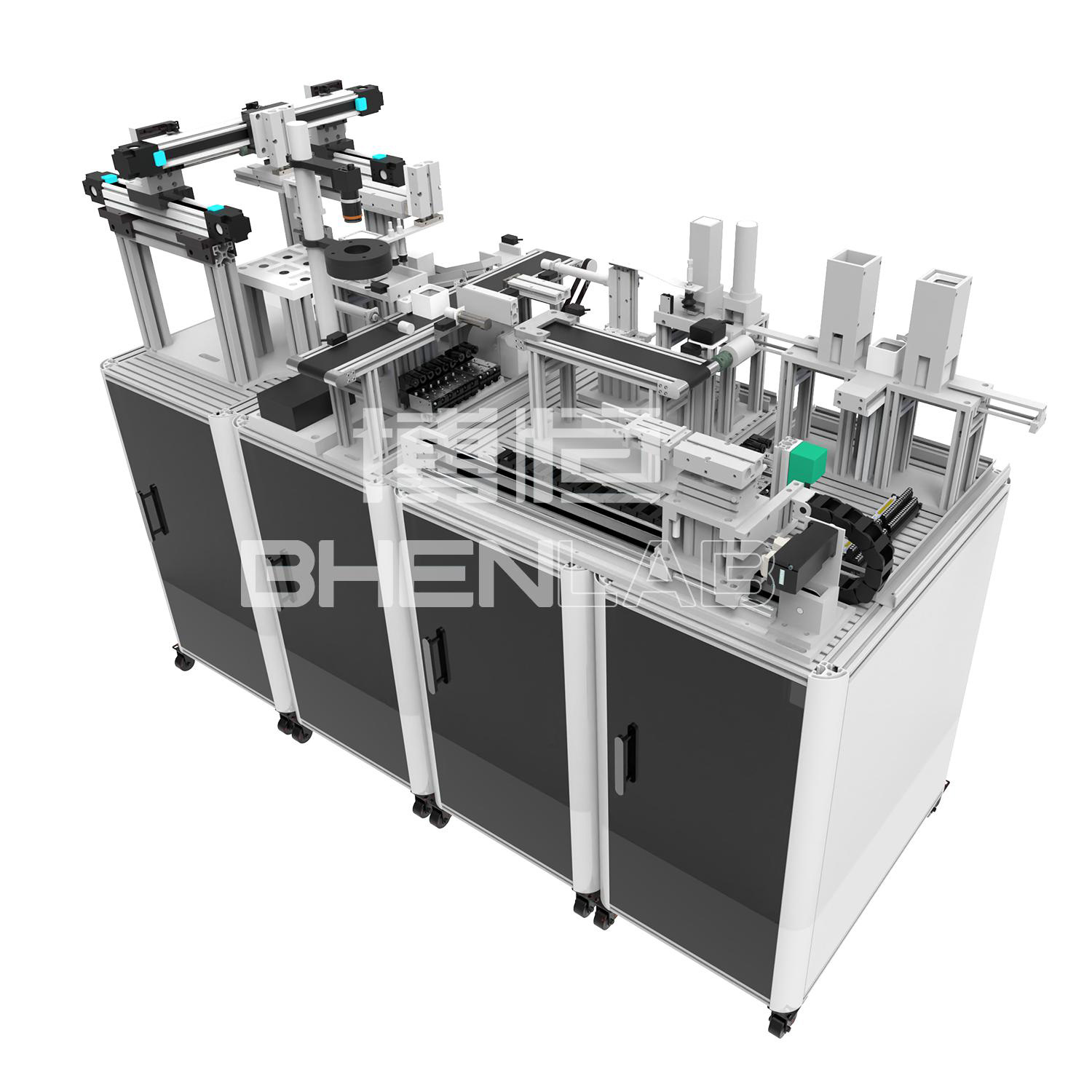

Group Display

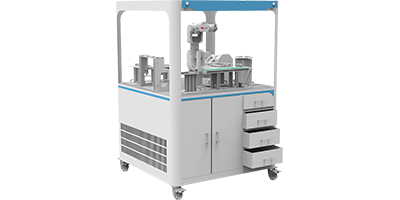

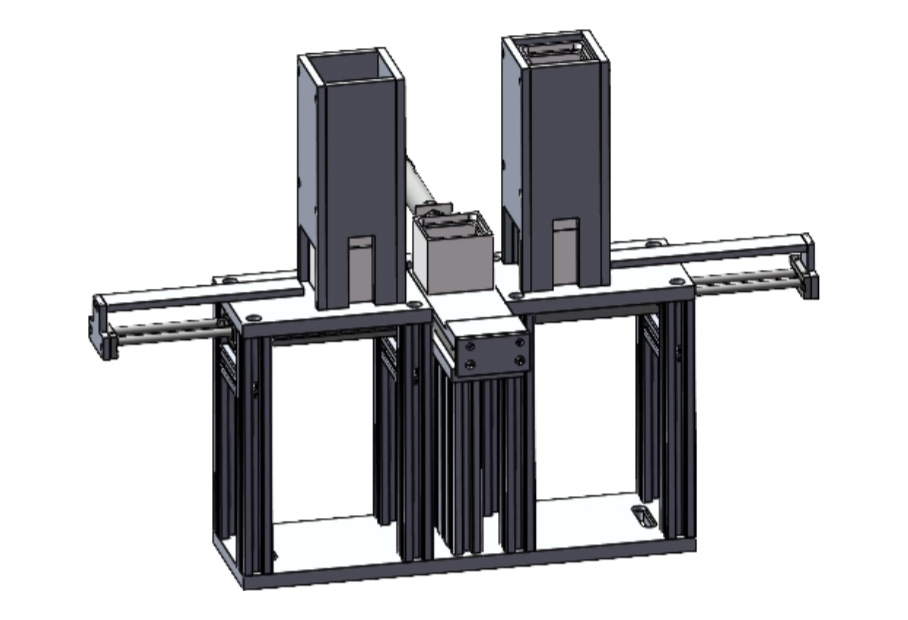

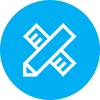

Material supply workstation

The main body of the feeding workstation consists of a bottle feeding unit, a bottle information reading and writing unit, and a slide table manipulator. As shown in the figure, it is the bottle feeding unit of the feeding workstation.

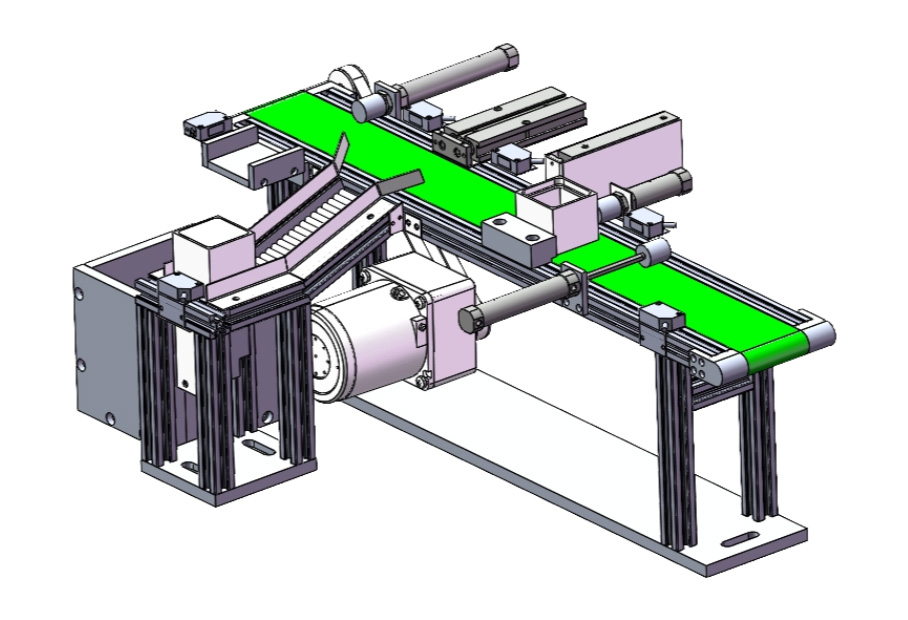

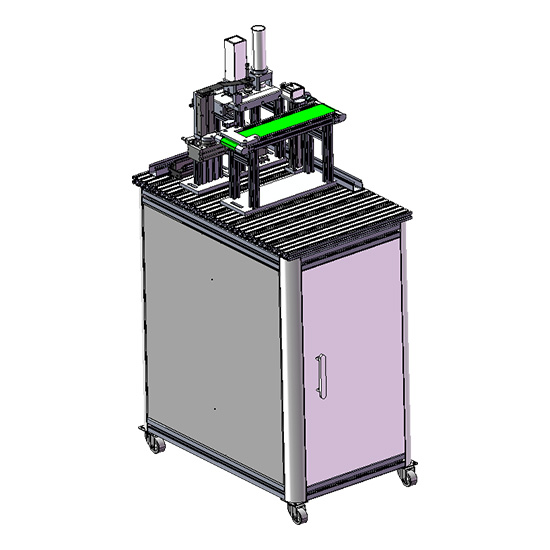

Assembly workstation

The assembly workstation mainly consists of an assembly material feeding unit, an assembly unit, an order information recognition module, and a horizontal conveying unit.

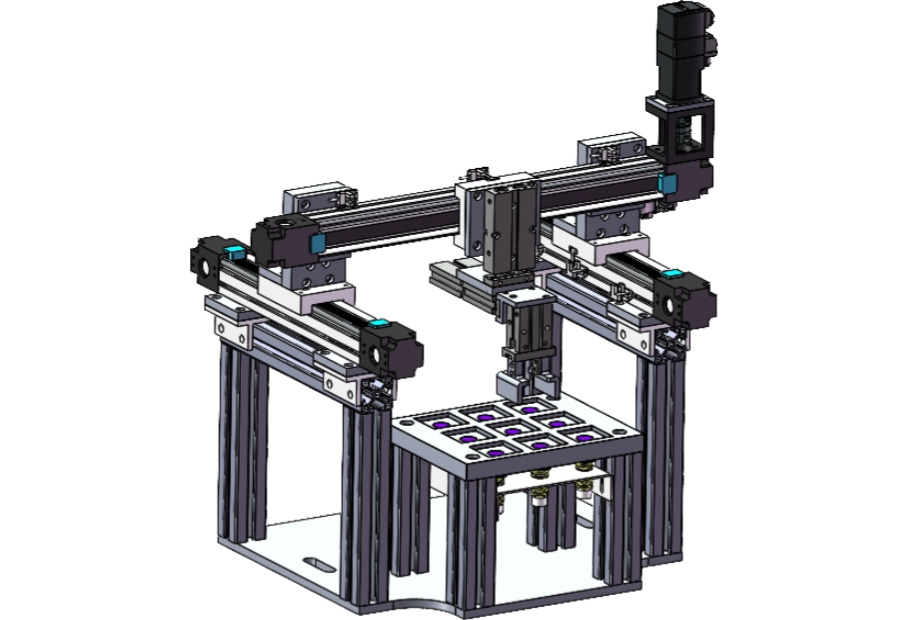

Detection workstation

The inspection workstation includes visual inspection unit, upper cover assembly unit, vertical conveying unit, etc. After the assembly workstation is completed, the mechanical arm handling unit transfers the material from the horizontal conveying unit to the vertical conveying unit. After passing through the visual inspection mechanism, it determines whether the material is covered and transported into the warehouse or kicked for waste recycling.

Storage workstation

The storage workstation mainly consists of gantry manipulator module, information reading module (RFID), and storage platform module. Before the operation of the storage workstation, the materials of the detection workstation should be slid onto the storage track. After the information reading module reads the content and recognizes it, the corresponding storage location is allocated based on the read information. The gantry robot module grabs the assembled products and transports them to the corresponding storage location.

Product Introduction

The virtual real combination production line training device is a modular teaching workstation for automatic assembly. The workstation covers various technological applications such as interconnection control technology, transmission technology, human-computer interaction technology, visual inspection technology, mechanical technology, sensing and pneumatic technology, and various industrial fieldbus communication technologies. Among them, the interconnection control and human-computer interaction technology carriers are equipped with top domestic and foreign brands, ensuring the stability and reliability of the system's teaching process.